PETG (Axpet®)

Polyethylene terephthalate glycol-modified (PETG) is a durable and long-lasting material for interior applications. PETG has favourable product qualities, is food-safe, resistant to chemicals, virtually inflammable and can be very easily thermally worked. Furthermore, it has outstanding mechanical properties. It is used for machine covers, glazing, shop fitting and trade fair construction, as well as in the furniture industry.

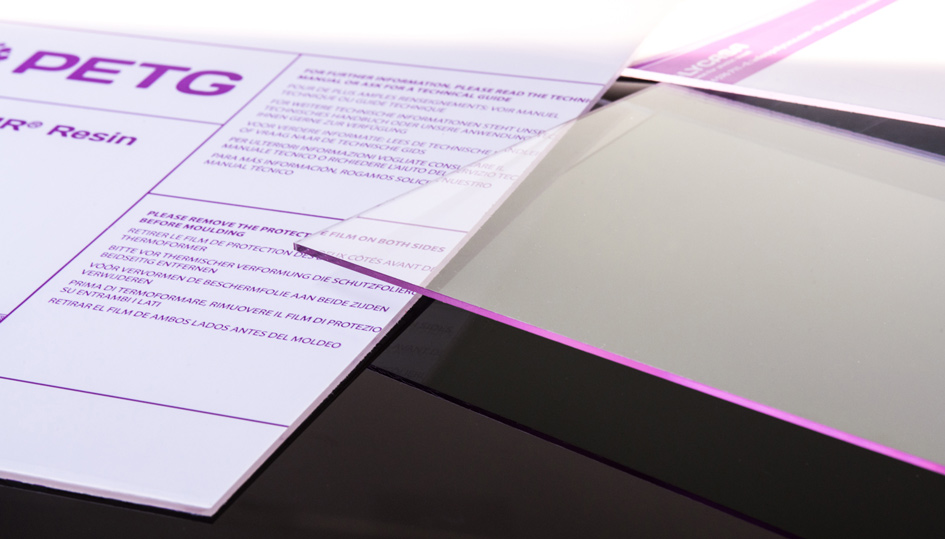

Axpet® – transparent cold bend plastic sheets

Axpet® designates solid sheets made of polyester manufactured from PETG. They have high impact resistance, good fire protection classification and are food-safe. In addition, Axpet® is resistant to chemicals and fully recyclable. This material is ideally suited for merchandise and advertising presentations, for example, for displays, price tags and containers and also for packaging food and pharmaceutical products.

Axpet® has outstanding cold-bending qualities, flexibility and good chemical resistance. Besides its environmentally friendly features, the material stands out due to all the advantages of high-quality polyester sheets. These advantages can be seen in the easy and cost-efficient processing and good optical qualities.

There are various versions of Axpet®: colourless, translucent white, opaque white and UV-protected.

Axpet® at J. Schwarz

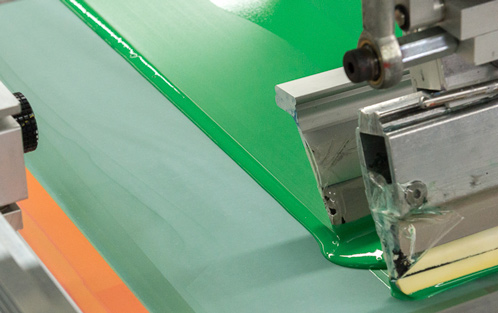

J. Schwarz processes Axpet® as a particularly suitable material for 3D milling with 3-axis and 5-axis machines. The maximum 3-axis processing area is 4000 x 2000 mm, and the maximum 5-axis cube shape encompasses 2000 mm x 1000 mm x 600 mm. A total of six milling centres are available.

Warm work takes place using blade and hot wire benders, and cold forming using a 80-ton folding press. Lasing and diamond and flame polishing are possible types of machining.