POM – Polyacetal (Sustarin®)

Polyacetal (POM, also polyformaldehyde) is a high-crystalline thermoplastic. POM is used as an engineering plastic especially for precision parts because of its high degree of stiffness, low friction coefficient and outstanding dimensional and thermal stability. It also features a high degree of strength, hardness and stiffness in a wide range of temperatures. Polyacetal maintains its high degree of toughness to -40 °C, demonstrates high wear resistance, a low friction coefficient, high warm dimensional stability, good sliding qualities, electrical and dielectrical properties, as well as low water absorption; it can also replace metal in many cases. Its natural colour is white due to its high crystallinity; however, the material can be dyed in all muted colours. In addition, it is suitable for operating temperatures up to 130 °C.

Sustarin® is a partially crystalline thermoplastic with the following properties: high dimensional stability, low moisture absorption, excellent sliding capability, high wear resistance, an ideal combination of strength, stiffness and toughness, low creep tendency, good machinability, as well as favourable electrical and dielectrical behaviour.

Sustarin® is used in particular for parts with especially high requirements for dimensional stability and optics, for example for gearwheels, bearings, sliding and spring elements, pump components, valve stems, gaskets, coupling components, gearbox parts, sorting and feeding devices, pump casings, coil bobbins, insulators and transformer housings.

Sustarin® at J. Schwarz

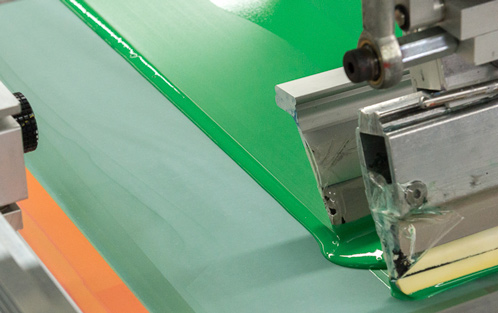

At J. Schwarz, Sustarin® is processed as a particularly suitable material for 3 & 5-axis 3D milling machines. The maximum 3-axis processing area is 4000 x 2000 mm, and the maximum 5-axis cube shape is 2000 mm x 1000 mm x 600 mm. A total of six milling centres are available.