Polystyrene (PS)

Polysterol (PS) designates a transparent, white foamed, amorphous or partially crystallized thermoplastic. Amorphous polystyrene is a very common plastic that is contained in many everyday products. Polystyrene is used as a thermoplastically processed material or as foam (expanded polystyrene). A common trade name for polystyrene foam is Styrofoam.

The properties of PS include resistance to aqueous alkali solutions and mineral acids; however, it is not to solvents such as benzene, ketones and aldehydes. Moreover, it is UV-sensitive. Solid amorphous polystyrene is crystal clear, hard and sensitive to impact. PS can be dyed in all colours.

Applications

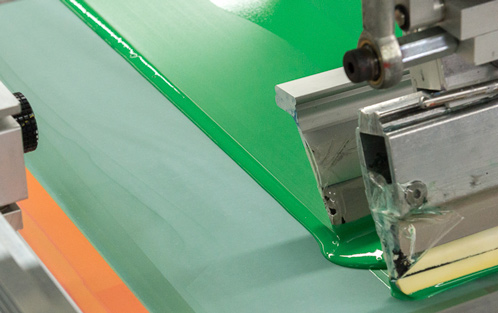

Polystyrene is used in electrical engineering due to its good insulating properties. It is used for insulating cables, manufacturing switches, coil bobbins and casings for electrical devices. Polystyrene foam is approved without restrictions in the food industry, for example, for yoghurt containers, blister packaging, etc. Furthermore, polystyrene can be completely recycled. Transparent films made of polystyrene are also made for packaging purposes. Films and sheets are manufactured using extrusion.

Polysterene foam is used as shock-absorbing packaging material or for thermal building insulation. Since polystyrene foam can be cut very easily with a hot wire foam cutter and is inexpensive at the same time, it has become established as a building material in architectural and model construction.

Polystrol at J. Schwarz

J. Schwarz processes Polystyrene by lasing or milling, as well as warm working using a blade or hot wire bender and cold working using a 80-ton folding press. A total of 6 laser cutting machines are available with processing areas of up to 3000 x 1500 mm.